Services

Construction, bluing and 3D printing

Home

I. Range of Services > Services

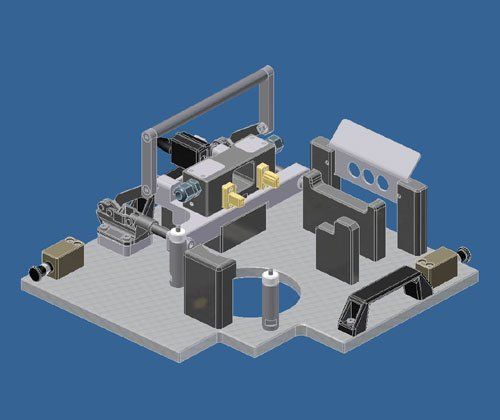

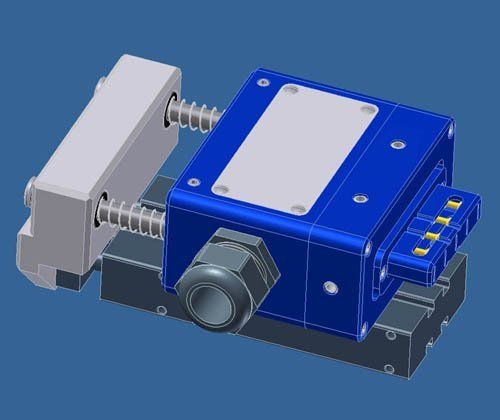

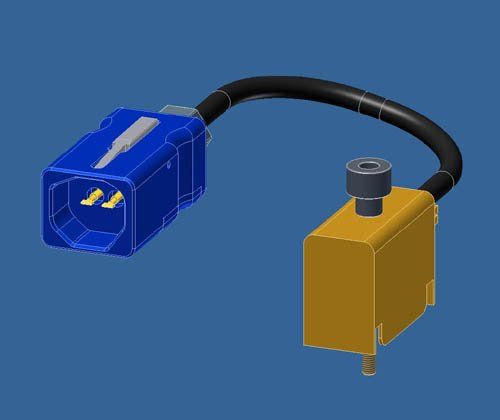

CAD designs in 3D with Autodesk Inventor

Our designs are based on Autodesk Inventor. We will create a datasheet for you with a technical drawing according to DIN standards, including a parts list and manufacturer specifications for purchased components, as well as a wiring diagram or connection plan for the cable assembly. The 3D models and datasheets will be provided to you electronically (STEP / DXF / PDF) so that you can integrate the data into your system.

Bluing according to DIN 50938

With the acquisition of our hot bluing system in 2015, we are able to carry out bluing work according to DIN50938 to prevent corrosion for you.

Our bluing bath is for records

up to a Maximum size

from 500 x 300 x 30 mm

suitable. The Basket size

for small parts

It has the following dimensions: 550 x 220 x 210 mm

Our

Burnishing day is Thursday. The

parts must be delivered the day before. Finished parts can always be picked up the following day.

3D printing

SLS parts

We manufacture our polyamide (PA12) components on an EOS Formiga P110 laser sintering system. This process melts powdered PA layer by layer using a laser to create a wide variety of shapes and is suitable not only for prototypes but also for high-strength end products. We typically use two materials: PA2200 (PA12) and PA3200GF (glass-filled PA12). The components can be subsequently machined, vibratory finished, and colored. The maximum build volume is 190 x 210 x 310 mm (W x D x H).

FDM parts

Our parts are manufactured on a STRATASYS F370 series printer. This process melts the filament (a "plastic string") layer by layer. Depending on the application, different filaments such as ASA or ABS-ESD7 are used. The completely enclosed and heated build chamber prevents warping of the parts. Any necessary support structures are built with a separate support filament, which is subsequently washed away from or within the part. The maximum build volume is 350 x 250 x 350 mm (W x D x H).

DLP parts

We manufacture parts from photopolymer resin using the P3 Origin Two from STRATASYS. This process uses liquid resin that is cured layer by layer using UV light. Different photopolymer resins are used, each with different properties depending on the application. From high-strength, hard components to elastomers with silicone-like properties, a wide range of applications is possible. This process is particularly suitable for delicate components with excellent surface quality (similar to injection-molded parts). The high dimensional accuracy and reproducibility of the components make it ideal for customer-specific small-batch production of end products. The build volume is 192 x 108 x 370 mm (W x D x H).